POSCO embraces giga steel, lithium as future growth engines

[THE INVESTOR] Korea’s top steelmaker POSCO plans to expand its premium high-strength steel products while seeking new growth engines as it gears up for further success in the next 50 years.

Ahead of its 50th anniversary next year, POSCO announced its future strategy that concentrates on enhancing its mainline steel business with its latest giga steel products, increasing profits in non-steel segments, as well as injecting 2.5 trillion won (US$2.18 billion) in developing future technologies over the next three years, according to the company on June 21.

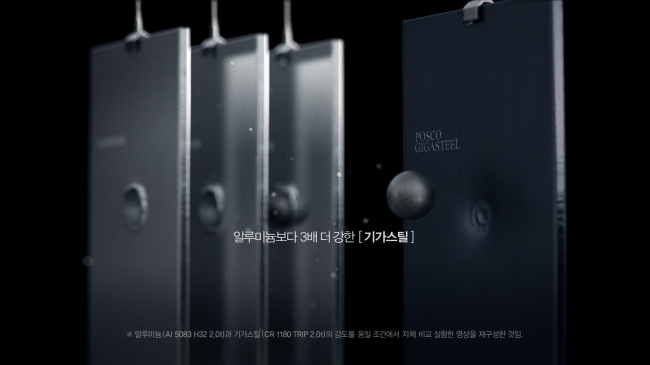

POSCO's gigasteel

Despite unfavorable market conditions, growing trade protectionism and Chinese steel supply glut, POSCO’s operating profit surged 18 percent on-year to 2.84 trillion won last year. By focusing on high quality steel products, the steel giant projects to increase profits to 5 trillion won by 2019.

The company plans to expand the production of its latest ultra-high strength steel giga steel, which is much lighter yet stronger than existing products.

POSCO’s giga steel boasts a tensile strength rated at more than 1 gigapascal, meaning it can withstand pressure of 100 kilograms or more per square millimeter.

The steel giant recently completed a manufacturing plant dedicated to giga steel production in Gwangyang, South Jeolla Province. The 255.4 billion won facility can produce some 500,000 tons of giga steel per year, enabling it to meet the increasing demand from global carmakers for lighter and stronger automotive steel.

POSCO has set eyes on expanding lithium carbonate to diversify its portfolio of non-steel segments as well.

In February, POSCO opened a lithium extraction plant at its complex in Gwangyang, starting the country’s first commercial production of lithium carbonate, a base material for lithium-ion batteries used in laptops and cell phones. The new plant is expected to roll out 2,500 tons per year -- enough to make batteries for some 70 million laptops.

Thanks to POSCO’s development of its own eco-friendly lithium extraction technology, the secondary battery suppliers, such as LG Chem, Samsung SDI and its affiliate POSCO ESM, can rely on the firm to meet the increasing demand of lithium-ion batteries.

POSCO is planning to expand its production capacity of lithium carbonate to 40,000 tons annually, in response to the soaring demand for lithium driven by electric vehicles and cell phones. The annual market demand for lithium carbonate has increased from 6,000 tons in 2002 to 66,000 tons in 2015. By 2025, the size is expected to increase to more than 180,000 tons.

POSCO’s future growth will be ensured with new businesses as well, including its natural gas storage segment, overseas independent power producers business, and new and renewable energy. POSCO is injecting 2.5 trillion won in its future business over the next three years, with goals to achieve 11.2 trillion won revenue by 2025.

The steel giant is also focusing on implementing advanced technology at its affiliates. It has incorporated AI-based technologies into its smart factories to manufacture high-quality steel while maximizing cost competitiveness.

By Ahn Sung-mi (sahn@heraldcorp.com)

EDITOR'S PICKS

- SK hynix profits soar on AI chip boom

- Korea enters clear growth path as Q1 growth hits 2-year high

- Hyundai, Kia seek to boost presence in China market

- 7 out of 10 wealthy Koreans offer grim outlook for 2024

- [KH Explains] Korean shipbuilding stocks rally: Real growth or bubble?

- [Hello India] Hyundai Motor vows to boost 'clean mobility' in India

- Eximbank to nurture regional development specialists

- [From the Scene] KG Mobility poised to take next leap

![[KH Explains] Korean shipbuilding stocks rally: Real growth or bubble?](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=141&simg=/content/image/2024/04/25/20240425050656_0.jpg)

![[Hello India] Hyundai Motor vows to boost 'clean mobility' in India](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=141&simg=/content/image/2024/04/25/20240425050672_0.jpg)

![[From the Scene] KG Mobility poised to take next leap](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=141&simg=/content/image/2024/04/24/20240424050621_0.jpg)